Zero Leakage Forged Steel A105 A350 Lf2 Body Soft Seat Primary Metal Seat Weld Overlay Inconel 625 Flange Floating and Trunnion Mounted Ball Valve

Package size per unit product 150.00cm * 150.00cm * 100.00cm Gross weight per unit product 1500.000kg Lead Time 15 days

Basic Info

| Model NO. | Q47 |

| Media | Oil |

| Material | Carbon Steel |

| Connection Form | Flange |

| Driving Mode | Worm Gear |

| Nominal Pressure | ANSI CLASS 150-900 |

| Channel | Straight Through Type |

| Structure | Fixed Ball Valve |

| Type | Fixed Ball Valve |

| Function | Blow-Down Valve, Relief Valve, Atmospheric Valve, Bypass-Valve |

| Temperature | Low Temperature |

| Standard | ANSI,DIN,JIS,GOST or Customized |

| Application | Industrial Usage, Water Industrial Usage, Household Usage |

| Construction | Single, Two and Three Pieces |

| Bore Design | Full Bore or Reduced Bore |

| Sealing | Soft and Metal-Seated |

| Connect | Flanged,Screwed, Socket-Weld |

| O Ring | Aed O Ring or Lip Seals |

| Seat Design | Primary Soft Seal or Secondary Metal Seal |

| Effect Seat | Single Piston Effect Seat or Double Piston Effect |

| Dbb | Double Block and Bleed |

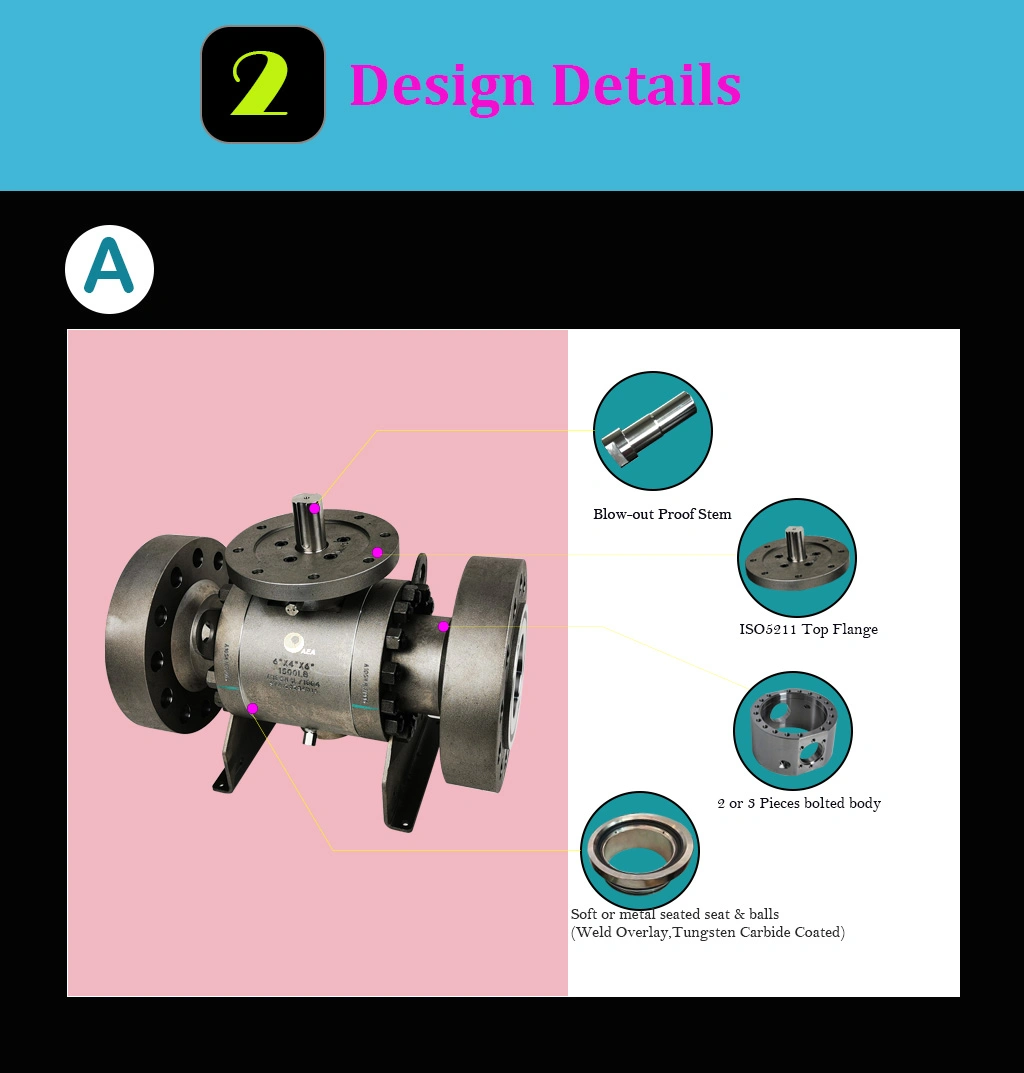

| Stem | Blow out Proof Stem |

| Static Device | Anti-Static Device |

| Fire Safe Design | API 607, API 6fa,ISO 10497 |

| Soft Seat | Enp Coating, Base Material |

| Metal Seat | Inconel Overlay or Tungsten Carbide Coated |

| Body | Bolted Body or Welded Body |

| Special | Nace Mr0175 |

| Transport Package | Standard Export Packing Seaworthy |

| Specification | 1000*1000*1000 |

| Trademark | AEA VALVE or Customized |

| Origin | China |

| HS Code | 848180 |

| Production Capacity | 50000 Tons/Year |

Packaging & Delivery

Package size per unit product 150.00cm * 150.00cm * 100.00cm Gross weight per unit product 1500.000kg Lead Time 15 days (1 - 1 Sets)To be negotiated ( > 1 Sets)

Product Description

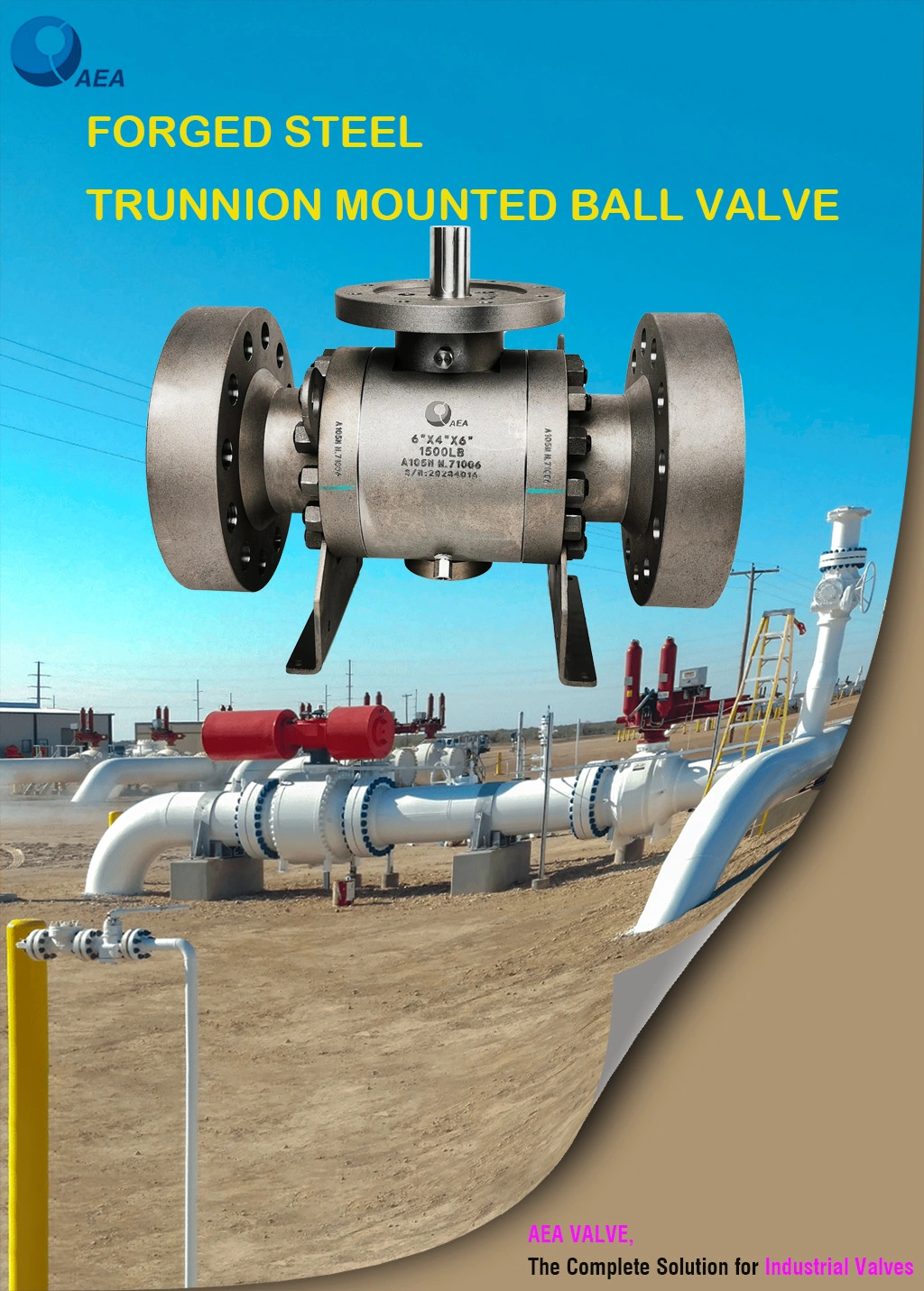

AEA Forged Steel Trunnion Mounted Ball Valve

| Size | 2" to 60" (50 mm to 1500 mm) |

| ASME Class | Class 150 to 2500 |

| Design Standard | API 6D |

Standards:

- Trunnion-mounted Ball Valve design complies to API 6D

- Valves offered with API 6D monogram

- Wide portfolio of Side-entry and Top-entry designs

- Fugitive emissions - Soft and Metal seated valves complies to ISO 15848-1, Class AH and BH

- Stem seal configurations tested to API 622 at Yarmouth Research labs, Maine, USA

- Firesafe design - Tested to API 607 and API 6FA

- CE Marking - Meets requirements of Pressure Equipment Directive 2014/68/EU, Annexure III, Module H

- PED Module B1 Design examination certificate (certified by DNV) available

- Atex - Meets requirements of Atex Directive 94/9/EC (ATEX), category 2 non-electrical equipment

- SIL3 - Safety Integrity Level SIL 3 certification to IEC 61508, certified by Exida/ TUV

- Valves successfully tested to Shell Design Evaluation Test, Procedure 77/300 for temperature -29 to 150 degree C (O rings) and -50 to 150 degree C (Lip seals)

- Pneumatic shell test conducted at 1.1 times rated pressure to check shell integrity, when required

Features that Add Value:

- Double block and bleed (DBB) feature - Valves are designed and tested for automatic cavity relief

- Anti-blowout stem design

- Coil springs used for consistent seat loading and lower operating torque

- Lip seals provided for low temperature services

- 2/3 stage Stem and 2 stage Body Joint sealing system; Primary O ring and Secondary graphite (in 3 stage stem, thrust washer is primary)

- Where tight shut off is required, Double piston effect (DPE) seats provided for redundancy in sealing

Versatile Solutions:

- Wide portfolio of Side-entry and Top-entry designs

- Options: Buried service, Cryogenic

- Offered with Electric, Pneumatic and Hydraulic Actuators

- In-house Tests Capabilities - Cryogenic Test, Pipe Bending Test, Vacuum Test and Fast Closure Test

Accessibility to all the valve internals from the top

In-line valve maintenance, without disassembling the valve from the pipeline

Reduces maintenance downtime

Body cover joint not exposed to pipeline stresses

Trunnion-mounted Ball Valves - Top-entry Design Special Features: Accessibility to all the valve internals from the top In-line valve maintenance, without disassembling the valve from the pipeline Reduces maintenance downtime Body cover joint not exposed to pipeline stressesValves - Top-entry Design

Special Features:

- Accessibility to all the valve internals from the top

- In-line valve maintenance, without disassembling the valve from the pipeline

- Reduces maintenance downtime

- Body cover joint not exposed to pipeline stresses

Trunnion-mounted Ball Valves - Top-entry Design

Special Features:

- Accessibility to all the valve internals from the top

- In-line valve maintenance, without disassembling the valve from the pipeline

- Reduces maintenance downtime

- Body cover joint not exposed to pipeline stresses

Send to us